预测性维护—数字孪生

本文摘要:(由ai生成)

预测性维护在航空业中通过数据分析和AI预测飞机潜在故障,帮助航空公司主动规划维修。关键发展点包括选适合的传感器、定制系统和数据物理解释。法国VibraTec集团是机械声学振动专家,提供创新解决方案增强产品可靠性。懿朵科技作为VibraTec的中国合作伙伴,提供振动噪声控制技术,服务于轨交、汽车、航空航天等,包括整车优化、软件开发、减振降噪产品设计、故障诊断与健康管理等服务。

Context & Issue

Context & Issue

Key Development Points

Key Development Points

Extensive sensor database for measuring various physical parameters: acceleration, displacement, pressure, acoustics, rotation speed, deformation, temperature, current, etc. Analog and digital sensors (MEMS) On-board or ground instrumentation (endurance or performance benches).

On-board instrumentation (anemometer, altitude, temperature, incidence, yaw) Test-specific instrumentation: pressures, gauges, anemometer Load characterization Response characterization: virtual sensor = maximum stress

Hardware selection based on: Host site: on-board or ground-based, Type of storage or transfer, Conditioners required for sensors, Sampling frequency, in-situ processing possibilities, Number of measurement channels, Type of processing required. Possibility of working with hardware already installed. Recording triggered by operating parameters, incidents or continuously.

Results & Benefits

Results & Benefits

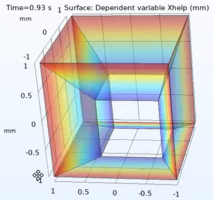

Feedback: field feedback / endurance bench testing of components Simulation: damage calculation / digital twin (sensor signal/damage transfer)

Validation of whether or not to replace the component during the next maintenance campaign Planning of an urgent maintenance task to replace the faulty component

法国VibraTec集团,成立于1986年,拥有超过 37 年的经验,是复杂机械、声学和振动现象方面的专家。作为国际知名的咨询公司,Vibratec致力于研究开发务实和创新的解决方案,使产品、基础设施和设备更加可靠、耐用和安静。

懿朵科技,总部位于上海,作为法国VibraTec集团在中国区独家合作伙伴,是以振动与噪声控制为核心的高新科技企业。凭借多年行业经验及算法积累,懿朵科技为轨道交通、汽车行业、航空航天等领域提供整车及零部件优化、软件开发、减振降噪产品设计、故障诊断与健康管理、环境振动噪声测试与预测、专业工具/软件销售等服务。在追求卓越的道路上不断创新,为客户提供技术支持与解决方案。

登录后免费查看全文

著作权归作者所有,欢迎分享,未经许可,不得转载

首次发布时间:2024-04-20

最近编辑:13天前

还没有评论